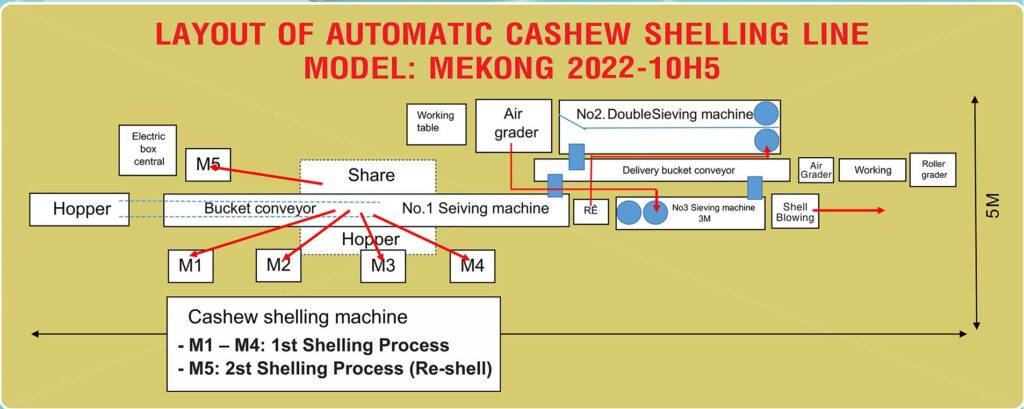

Application of Automatic cashew separating system:

Used in separating cashew kernel and cashew shell, uncutted after automatic cashew shelling machine.

Proces flow chart:

Advantage features of automatic cashew separating system:

The automatic cashew separating system is designed by MEKONG TECH GROUP inluded Main vibration sieving machine to separating cashew shell, uncutted and cashew kernel, Air grading machine to separating cashew shell with uncutted cashew , Centrifugual to separating uncutted, unscoop, Secondary Vibration sieving machine to separating the second cashew kernel and cashew shell, uncutted, is returned from roller grading, roller grading machine to separating cashew shell and uncutted, unscoop cashew.

Equipement one delivery bucket conveyor and air grader and to roller grading machine to collect unpeeled cashew kernel and separating small cashew shell to out cashew kernel, with this system can remove 98 % cashew shell in unpeeled cashew nut, contribute saving 70 % manual labour.

Electric control system is equiped two model control manual each equipment in system and auto model automatic all equipment in system.

The system has a highly compatible , easy to connect different types of cashew shelling machine.

The cashew separating system can be run independent or linked with more system into one big automatic cashew separating system for big cashew processing plant 20-100 ton per day.

Easy operation and maintenace.

Specification of automatic cashew separating system:

Model | VN-h1 | VN-h2 | VN-h4 | VN-h5 | VN-h6 |

Capacity(kg) | 200-300 | 400-600 | 600-800 | 800-1000 | 1500-2000 |

Power (kw) | 10 | 12.5 | 15 | 15 | 20 |

Power source (V) | 380 V, 3 phase, 50 Hz | ||||

Dimension (m) | 5x3x2.5 | 15x2x3.5 | 15x5x3.5 | 15x5x3.5 | 15x5x3.5 |